We have established for China steel & iron industry development by the government 60 years ago. We tailor made variety types of blowers and fans for all application requirements in steel & iron plant.

Sintering Plant (Pellet Plant)

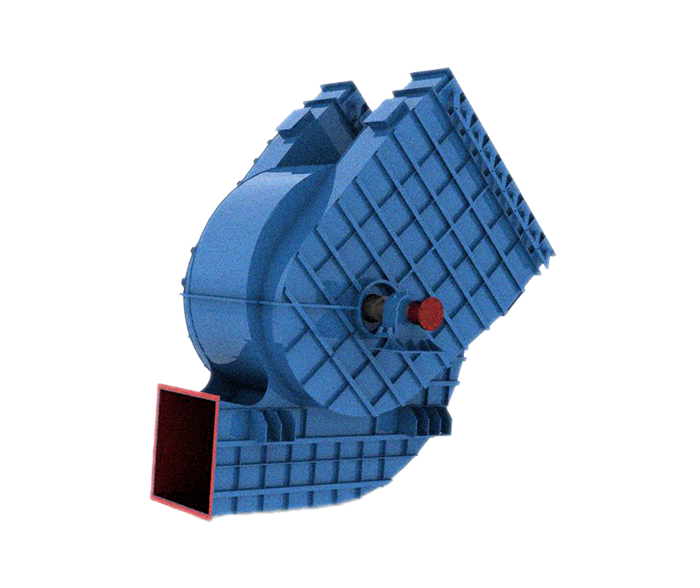

In the sintering process, we can deliver the process fans which includes, Cooling air fan, Recuperation fan, Exhaust gas fan, Dedusting fan. The fans are specific designed to suitable for high temperature and high dust contents working condition, in general, we can delivery the centrifugal type blower with capacity:

- Flow rate 1,400,000 Nm3/hr (330Nm3/sec);

- Installed motor up to 9800kW

.jpg) .png) Coke Ovens Plant,

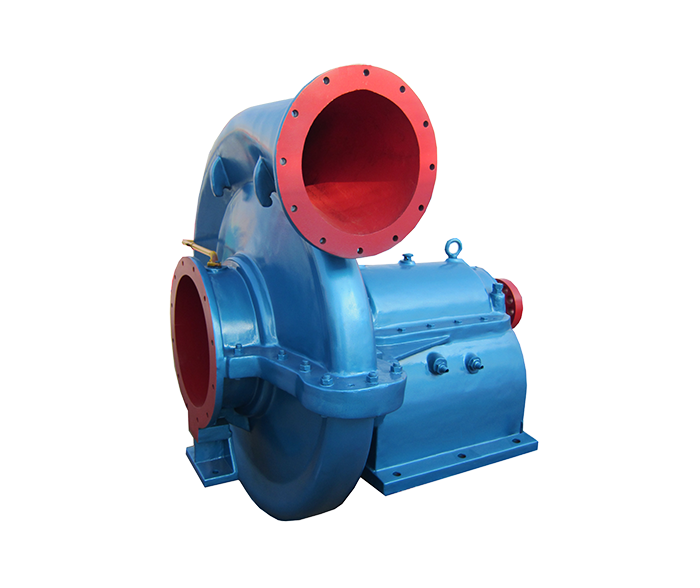

Coking process generates gas and/or flue gas in several stages, we have profound understanding on the flammable gas and delivered hundreds of gas fans, gas blowers for coking plant. The capacity of our coking gas blower is continuing increase together with coke oven size in China.

- Flow rate 300,000 Nm3/hr, pressure rise in between 18 - 25kPa;

- Installed power up to 2500kW;

Blast Furnace System

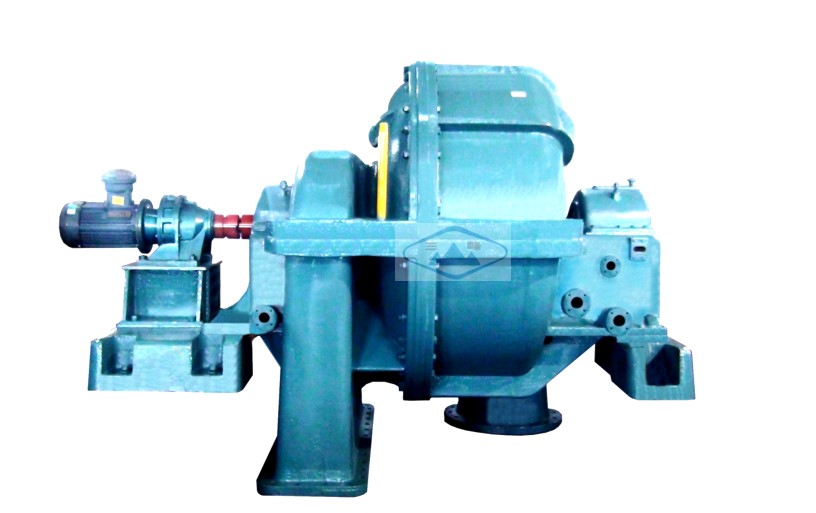

We also have delivered plenty of fans and blowers which required by blast furnace on different stages, include the blast furnace coal gas, in addition, provide fans and blowers for limestone kiln as well. Gas boost fan also in our scope which generated by blast furnace and recycled on multiple process of the steel plant.

Converter System,

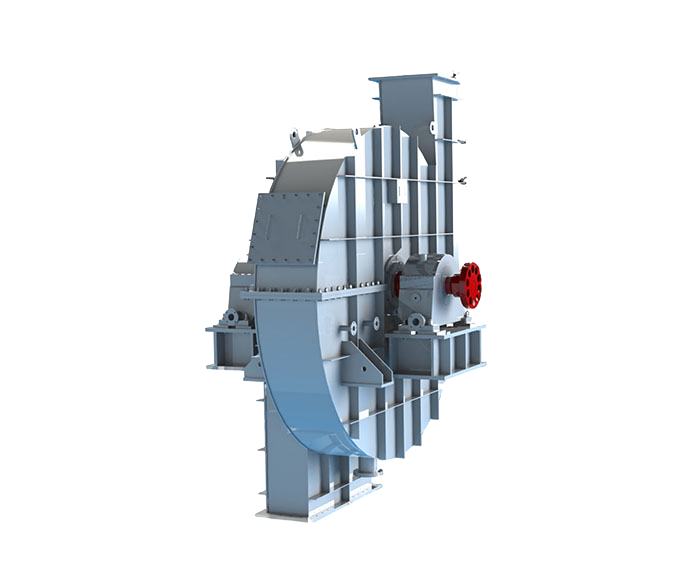

The wet scrubbed converter tail gas is flammable and with dust, to cooperate with the dedusting requirement, dedusting fan was set up to handle it. SFT have accumulated plenty of experience through hundred of projects in China market, to provide reliable, more tough design to cope with this dangerous and easy wearable working condition.

For this type of blower,

- Maximum flow rate 350,000Nm3/hr;

- Pressure 18 – 30kPa;

- Installed motor up to 4000kW;

DeSOx, DeNOx, and Dedusting boost fan,

The steel plant have several processes can produce flue gas, prior to emission to the chimney, those flue gas need be treated by desulfurization (DeSOx), denitration (DeNOx) and dedusting. We have provided movable blade adjustable axial fan and centrifugal fan for such process respectively subject to the application.

Subject to the working condition and project budget, we can provide both centrifugal and static/movable blade adjustable axial fan for such application;

For the centrifugal type we can handle the flue gas

- Flow rate up to 1,500,000Nm3/hr,

For the axial type

- Flow rate up to 3,600,000 m3/hr

.png)  Contact Us Ms. Liu Huan Mr. Shang Qian

Mobile: +86 159 7194 4772 Mobile: +86 186 7274 3699

Email: sftplh@qq.com Email: sftpshang@qq.com

|